Human-Robot Collaborative object transportation task

In the Human-Robot Collaborative object transportation task, the human operator defines the object trajectory, and this information is shared with the robot through the Augmented Reality interface, developed on HoloLens 2. The AR platform assists the operator during the initial grasping phase and provides real-time visualization of the robot state and applied wrenches. Throughout the task execution, an admittance control scheme is employed to reduce the wrenches applied on the object. In this way, the manipulator acts as an active agent, since it limits the generalized forces acting on the object, by means of an admittance controller framework.

Decentralized admittance control for a multi–manipulator system: theory and experiments

A decentralized control framework for cooperative object transportation with multiple robotic manipulators is presented. In particular two admittance schemes are designed in order to regulate external contact wrenches and internal interaction wrenches without a central unit or all-to-all communication. Each manipulator estimates the wrenches exerted by its teammates through a bank of consensus-based observers that exploits a strongly connected communication graph. These estimates feed two local admittance filters: an external filter, computing the reference object trajectory while limiting environmental wrenches, and an internal filter, generating the end-effector trajectory to minimize each robot’s contribution to internal wrenches. Experiments carried out with three 7-DOF Franka Emika Panda arms show a marked reduction of both external and internal wrenches, demonstrating the effectiveness and robustness of the proposed approach.

Decentralized admittance control for a multi–manipulator system: implementation and analysis

A decentralized strategy for object transportation is presented, assuming that the object is grasped by a team of N cooperative manipulators. The proposed strategy consists of two steps. First, each robot estimates the wrenches applied to the object by all the others robots, even without all-to-all communication. Second, an admittance control scheme is used to limit internal wrenches, preventing excessive stresses that could affect manipulation stability and object integrity. Stability is proven under the assumption of a spring connection between each robot end-effector and its grasping point on the object. A work cell with two 7-degree-of-freedom (DOF) and one 6-DOF robotic manipulators was used to validate the strategy. Experimental results show that the controller effectively reduces internal wrenches, confirming the feasibility and robustness of the decentralized approach in cooperative manipulation. This work has been presented at 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2025).

Robot-to-robot object handover in the absence of communication

An autonomous robot-to-robot object handover in the presence of uncertainties and in the absence of explicit communication. Both the giver and receiver robots are equipped with an hand-in-eye depth camera. The object to handle is roughly positioned in the field of view of the giver robot's camera and a deep learning based approach is adopted for detecting the object. The physical exchange is performed by recurring to an estimate of the contact forces and an impedance control, which allows the receiver robot to perceive the presence of the object and the giver one to recognize that the handover is complete.

Admittance control of a 7-dof collaborative robot for peg in hole task

Admittance control of a 7-dof collaborative robot for peg in hole task, where the target workpiece position is

unknown and the peg-hole clearance is small. Deep learning based hole detection and 3D surface reconstruction techniques are combined for

accurate workpiece localization. In detail, the hole is detected by using a convolutional neural network (CNN), while the target workpiece

surface is reconstructed via 3D-Digital Image Correlation (3DDIC).

This work has been presented at 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2020).

Admittance control of a fully-actuated hexarotor

Admittance control of a tilted-propeller hexarotor with a rigidly attached end-effector without force/torque sensor. An outer loop control governs the desired admittance behavior and an inner loop based on geometric control ensures pose tracking. The interaction forces are estimated by a momentum based observer. In this experiment, hard contact between the tool-tip of the rigid end-effector and a tilted wooden surface is experienced. More videos regarding such research topic can be found here.

Multi-robot coordinated control

A multi-robot system made up of four Crazyflie 2.0 quadcopters moves in a coordinated fashon. The quadcopters take off, move along a predefined circular trajectory, defined in Phython and sent to the Crazyflies via the Crazyradio, and finally land. The demo requires an external positioning system, the Loco Positioning System (LPS), that is in charge of providing the absolute 3D position of objects in space. It is in many ways similar to a miniature GPS system. The base of the system is a set of Anchors that are positioned in the room (compare to the satellites in GPS), they are the reference. The other part of the system is one or more Tags (compare to the GPS receiver) that are fixed to the object(s) that are to be tracked. By sending short high frequency radio messages between the Anchors and Tags, the system measures the distance from each Anchor to the Tags and calculates the position of the Tags from that information. All information needed to calculate the position is available in the Tag which enables position estimation on board of the Crazyflie.

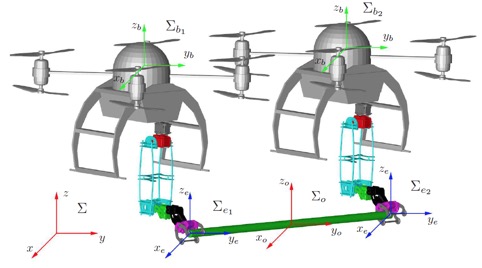

Coordinated control of multiple-Unmanned Aerial Vehicle Manipulators

The videos show the evolution of two Unmanned Aerial Vehicles (UAVs) equipped with 6 DOFs robotic arms, hereafter called arial manipulators, involved in a coordinated motion experiment.

In detail, on the left one aerial manipulator is in charge of pointing a camera, attached on its end-effector, at the other one: the field of view must be kept even when the pointed UAV is moving.

A supervisor monitors the distance between the two UAVs, which should be larger then a safety threshold, and selects a suitable compound behavior aimed at restoring such a safety distance when needed.

It can be seen, approximately at time 34 s, that the aerial manipulator, labeled as UAVM1, moves toward the other one, labeled as UAVM2, which, in turn, reacts by moving forward in order to restore the

safety distance (still keeping the field of view).

On the right a trajectory is commanded to a virtual object located at centroid of the two endeffectors, and the UAVMs have to move in a coordinate fashion by keeping the distance between them constant.

The videos show the coordinated control of three aerial-manipulators. More in detail, one UAV is equipped with a 6 DOFs manipulator and acts as a Transporting Robot (TR). The TR is in charge of reaching a grasping point, grabbing a rigid bar and transporting it to a deployment point: this is repeated two times (i.e., for two different bars).

A couple of small UAVs, which plays the role of Auxiliary Robots (ARs), is tasked with pointing a camera toward the TR, keeping different fields of view of the same scene; moreover, the ARs should maintain a safety distance with respect to the TR (in order to reduce the airflow disturbances) and avoid several obstacles during the entire flight.

The video on the left shows the scene seen by one of the ARs, while the video on the right reports a simulation of the same case study.

Aerial Manipulator Impedance Control

Preliminary experiments of impedance control have been conducted on an Aerial Manipulator. As first step, only manipulator impedance control has been tackled out with the platform suspended from a cable. The video reports the effect of a perturbation applied to aerial platform, by impulsively changing roll/pitch angle. Since the controller compensates for the end-effector displacement induced by roll/pitch angle changes, when a perturbation is applied to the aerial platform, the system becomes unstable, as shown in the left half of the video. By adding active damping to the platform the stability is fully recovered, as it could be appreciated on the right half of the video.

The video shows the impedance control of the six DOFs arm manipulator: the end-effector is commanded to reach a point located inside the cardboard box; soon after the contact, between the end-effector and the box, is established the interaction force increases and the controller reacts in such a way to make the system compliant in order to keep such force bounded. In the right half of the same video shows the behavior of the arm under the effect of external disturbances applied by human agents: the end-effector is tasked with keeping the initial position.

The video reports a flight test in which the end-effector is commanded of keeping the rest position while external disturbances are applied by means of a rope: when the rope is pulled the system complies in the direction of the applied forces and approaches the rest position as soon as the rope is released.

Cooperative Impedance Control of Aerial Manipulators

For a system constituted by a couple of aerial manipulators grasping an object, two impedance control laws are adopted with the aim of

achieving bounded internal and external contact forces. Based on the desired object trajectory and the measured contact generalized forces, an impedance filter

computes a new objectÕs reference motion, which, in turn, is transformed into a desired end effector trajectory via the the kinematic closed-chain constraint.

Then, on the basis of the output of the previous layer and the measured end-effector forces, a second impedance filter determines the reference values for the

end-effector trajectories. Once the reference trajectories for the end-effectors are computed, an inverse kinematics algorithm computes the desired values of

vehicles position, yaw angles and manipulators' joints (controlled variables). Finally, a motion controller is in charge of achieving such desired motion

for the controlled variables. The proposed control scheme has been tested in simulation in Matlab/SimMechanics environment.

For a system constituted by a couple of aerial manipulators grasping an object, two impedance control laws are adopted with the aim of

achieving bounded internal and external contact forces. Based on the desired object trajectory and the measured contact generalized forces, an impedance filter

computes a new objectÕs reference motion, which, in turn, is transformed into a desired end effector trajectory via the the kinematic closed-chain constraint.

Then, on the basis of the output of the previous layer and the measured end-effector forces, a second impedance filter determines the reference values for the

end-effector trajectories. Once the reference trajectories for the end-effectors are computed, an inverse kinematics algorithm computes the desired values of

vehicles position, yaw angles and manipulators' joints (controlled variables). Finally, a motion controller is in charge of achieving such desired motion

for the controlled variables. The proposed control scheme has been tested in simulation in Matlab/SimMechanics environment.

The research leading to these results has received funding from the European Community's Seventh Framework Programme under grant agreement

n. 287617 (collaborative project ARCAS). More technical details can be found in:

F. Caccavale, G. Giglio, G. Muscio, F. Pierri, Cooperative Impedance Control for Multiple UAVs with a Robotic Arm, 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2015).

The code adopted for the paper simulations can be downloaded here:

Behavioral control of Aerial Manipulators

A behavioral control system for Unmanned Aerial Vehicle Manipulators (UAVMs) has been developed within the European Project FP7-IP: Aerial Robotics Cooperative Assembly System (ARCAS). To attain multiple control objectives simultaneously a library of elementary behaviors has been developed; then, multiple elementary behaviors are combined, in a given priority order, into complex tasks (compound behaviors); to this aim the Null-Space-based Behavioral (NSB) approach has been adopted.

Distributed Fault Detection, Isolation and Accommodation for multi-robot system

Distributed Fault Detection and Isolation of a multi-robot system constututed of mobile Khepera III robots. The proposed solution is based on a distributed observer-controller schema where each robot, by communicating only with its direct neighbors, is able to estimate the overall state of the system. Such an estimate is then used by the controllers of each robot to achieve global missions as, for example, centroid and formation tracking. The information exchanged among the observers is also used to compute residual vectors that allow each robot to detect failures on any teammates, even if not in direct communication. The proposed strategy considers both recoverable and unrecoverable actuator faults. When the robots are subject to unrecoverable faults, the faults are isolated from anyone of the teammates by means of a distributed fault detection and isolation strategy; then, the faulty robots are removed from the team and the mission is rearranged.

Grasp force and wrist impedance control

A control framework for an arm/hand systems aimed at controlling internal forces exchanged between the fingers and the grasped object, and enforcing a compliant behavior in presence of an environmental interaction is presented: a dynamic planner computes the motion references for the fingers by using the contact force feedback, while an impedance control, with compensation of the dynamic effects exerted by the hand on the wrist, is designed for the arm. The experimental setup, available at the Computer Science Robotics Laboratory of the Rensselaer Polytechnic Institute (RPI), Troy, consists of a Barret WAM with 7 degrees of freedom and a wrist-mounted 6-axis force/torque sensor, and a BarrettHand, attached on the arm wrist, with joint torques sensors and tactile sensors providing 96 cells of tactile-array data spread across all three fingers and the palm.

Control of bimanual robotic systems

This video shows kinematic control of a planar bimanual arm/hand system. Three experimental case studies have been considered.

- Motion control in free space. Coordinate motion is performed without any physical interaction between fingers.

- Grasp reconfiguration. The fingers slide on the object surface to achieve force closure.

- Coordinated motion with object. Motion of a card box along the planned trajectory.